You want to warm something, but do not know how? Take advantage of our 30 years experience from the highest classes of motorsport to solve your problem!

We design, construct and produce customized solutions, From the individual prototypes up to x times series production.

For a well-known drug manufacturer, this project had one conditioning Heating to realize. Pipes, mixers and motors had to be preheated and kept warm. This is the result easy material flow guaranteed without losing time through long warm-up phases.

Our heaters have been running there for many years without incident in the "24/7" operation.

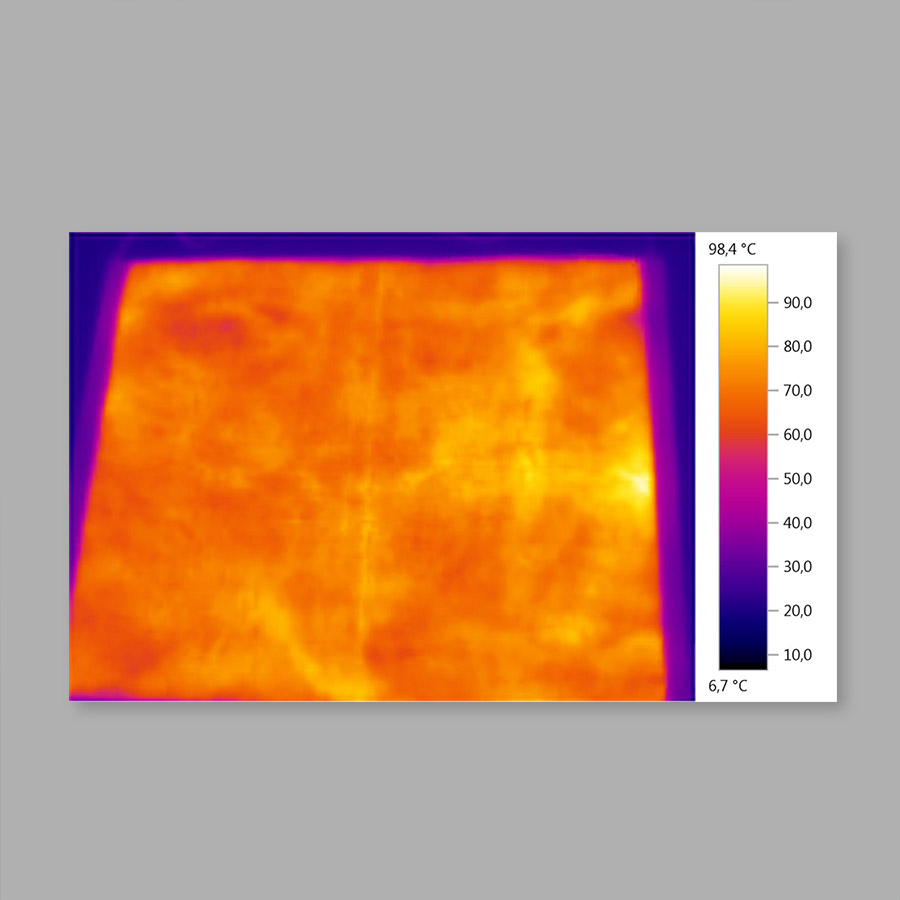

We have one for one of the leading sporting goods manufacturers Heating jacket designed for heating the outer shell of ski boots, The aim of the heating is to make the plastic soft and plastically malleable, so that it can be adapted in the further process to the individual shape of the customer's foot.

The big challenge was to heat up very quickly (only about 7 minutes), but at no point to overheat. Other heating techniques have been found in appropriate tests to be unsuitable, too uneven and too slow here was the warming.

Only by our superior heating technology we could meet the high demands and very fast reach the required temperature without damaging the smooth surface finish due to uneven heat distribution.

We have made several thousand pieces that have been in operation for many years. To date 0% failure rate!

In the World Rally Car World Championship, for example, driving in Sweden in extremely wintry conditions. The sometimes enormous cold would require a long warm-up phase of the spring elements, which is simple but not before starting.

That's why we have one here Heating the shock absorbers which already ensures the start of the special stage for constant chassis characteristics.

The specifications for this project were warm up quickly and evenly under maximum utilization of the available area. Some breakthroughs for handles and tube outlets, etc. had to be taken into account as well.

However, the main focus here was the reliability and durability. The Heating Jackets must be removed at regular intervals and reassembled. Any mechanical stresses occurring during this must be easily overcome. An exchange would be much more costly in this case than the heater itself, since the heaters are contaminated during operation and thus would have to be disposed of as extremely expensive hazardous waste.

We have produced about 200 pieces here, failure rate to date 0%!

Several years ago we received a very special request if we "heating elements"Can deliver, which are designed for a flat, but also very thin and permeable to laminating resin, Furthermore, holes should be installed anywhere without damaging the heater or even putting it out of service.

Of course, the corresponding resistances and dimensions had to be adhered to. We have all been able to meet these tricky requirements, so that now we have the 150 passenger carriages with our electric underfloor heating drive through the countries.

What to do if one extensive contraption tempered must, however, a pre-heating in a stationary oven ausscheidet because of too fast cooling outside? Quite simply, call KLS and order a matching heating mat!

Said done, component remains warm and can be joined.

Problem solved, customer happy (we too).

runflat- or so-called UHP (ultra high performance) tires usually have very stiff tire sidewalls. At correspondingly low temperatures, dangerous damage to the tire bead may occur during assembly. These can lead to air loss while driving and, as a result, to tire blowouts at high speeds.

To prevent this, a large automotive supplier has commissioned us with the construction of a tire bead heater.

We then produced and delivered many hundreds of them successfully. In daily use, our products have proven to be the best.

floating - In a warm, high-percentage salt water solution, you float on top of it almost weightlessly and can completely relax the body. Sounds like a very pleasant wellness treatment, as long as the water does not cool down in these 30-60 minutes.

We have based on our proven Carbon fiber heating designed a system that is laminated directly into the bottom of these approximately 2 × 2.5m GFK tubs. During the Floating process will be about it then very flat, quickly and evenly reheatedto prevent the salt solution from cooling.

Since 2011, we have worked together very successfully with the leading manufacturer of such floating systems.

High-tech HD cameras need a certain operating temperatur around optimal shots to create. Depending on the location of the film, this may mean that the camera, for example, overcools overnight and then by idling o.ä. time-consuming to operating temperature must be brought.

The heater we designed for this was probably the largest ever built with dimensions of approximately 2.40 mx 1.75 m.

The impetus to this revolutionary development Did not come as you might think of the highest class of motorsport, the formula 1. The idea of our rim heater was in cooperation with a DTM (German Touring Car Masters) private team born.

The temperature of the rim not only indirectly affects the temperature of the tire, much more decisive is the influence on the trapped air and thus on the tire pressure! We then produced a carbon molding that was individually adapted to the respective rim inside contour and coated it on the outside with our heating technology.

This is how a product was created perfect handling and function, As a result, many hundred of them were successfully and reliably deployed in the DTM and naturally also in Formula One.

Sometimes the right one heating process in the truest sense of taste. For example, in a project that deals with heat up 50l stainless steel barrels went. In these barrels was freshly squeezed fruit juice and this should be pasteurized by the fastest possible heat pasteurized ie made durable.

The previous somewhat rustic method with an immersion heater, has negatively affected the juice by the enormous local heat of the immersion heater tastes.

With the heating technology of KLS, the heating was achieved quickly and evenly without affecting the taste. In this sense - cheers!

High performance

Heating Solutions

© 2019 KLS Motorsport Accessories